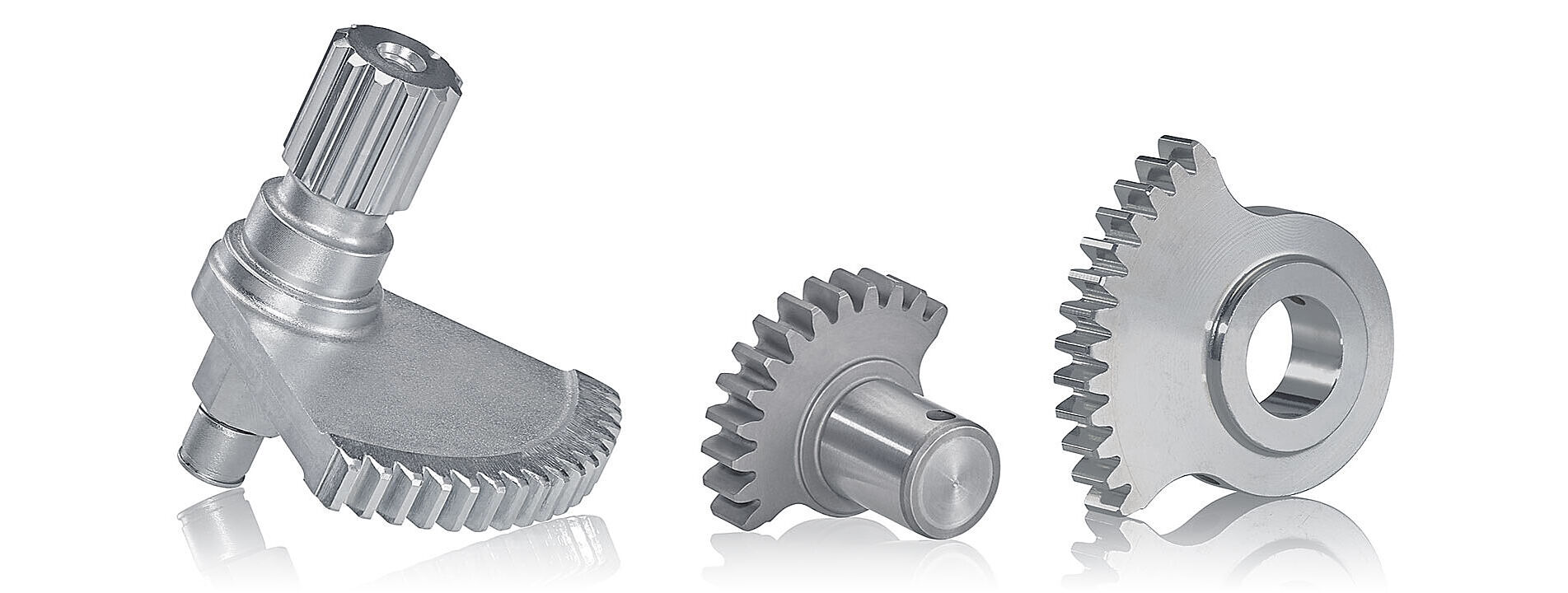

Special Gearing

Gearing with non-involute flanks is called special gearing. Involute gearing has a basic rack tooth profile in the form of a straight line, whereas special gearing does not. Nevertheless, special gearing and involute gearing are both produced using the hobbing method, which makes it possible to directly define various special gearings. A specially designed tool must then be used to make this special gearing. Generally, the tooth profile and the resulting geometry of the special gearing are determined via CAD. Based on the hobbing procedure, the appropriate mating gear can also be generated.

Compared to involute gearing, special gearing is difficult to standardize because the profile of the teeth also depends on the number of teeth on the smaller gear. For this reason, the tooth profiles of the gear pair must be precisely coordinated in order to guarantee ideal meshing and friction characteristics.

The teeth of a special gearing are often narrower at the root than the teeth of an involute gearing. Consequently, special gearings permit higher transmission ratios in a small space.

Cycloidal gearing is the most common type of special gearing. It is used in situations where the driving force creates propulsion from slow to fast speeds.

The reason non-involute gearing is sometimes preferred over involute gearing is because non-involute gearing has lower friction losses during slow to fast propulsion. Another advantage of cycloidal gearing is its greater tooth clearance, which makes it less susceptible to dust particles and dirt.

Special gearing as a customized solution

We offer special gearing solutions based on all of the special profiles that can possibly be generated – perfectly matched to your specifications and tasks – and based on complete workpiece data.

As a matter of course, Hänel Precision Gears uses materials that extend the service life of its products. Furthermore, maximized manufacturing precision is a hallmark of the Hänel brand. Superior Hänel quality is based on our employees’ many years of experience and in-depth expertise, not to mention ongoing investments in state-of-the-art production systems.

Schedule an appointment – there is no obligation – and let us demonstrate our expertise in special gearing. We look forward to hearing from you! We can produce high-precision special gearings tailored to your needs.