No future without a past

Milestones in Hänel's success

Today

The company, with some 80 highly qualified employees and trainees, manufactures ready-to-install gear components and modules for a wide variety of applications. Products are delivered to various industries, such as mechanical engineering, robotics, medical technology, energy, metrology, automotive and logistics engineering.

2024 - LIEBHERR gear hobbing machine LC 300

The Liebherr LC 300 CNC gear hobbing machine is equipped with automation and perfectly expands our capabilities, enabling us to achieve maximum efficiency even up to module 6.

2024 - Studer S 33 CNC universal external cylindrical grinding machine

Using our latest investment in a Studer S 33 CNC external cylindrical grinding machine featuring a WeStep automation cell, we can highly efficiently meet even the most demanding quality requirements.

2024 - Mitutoyo STRATO-Apex 776

The Mitutoyo STRATO-Apex 776 with greater measuring accuracy enhances our already outstanding quality standards for 3D coordinate measuring technology.

2019 - Investment in new machinery

New production systems installed: REISHAUER-CNC-RZ 260, STUDER S 141, MAZAK QUICK TURN 250 MSY, KLINGELNBERG P26, TYKMA ELECTROX

2018 - KLINGELNBERG-HÖFLER P 26 CNC Precision Measuring Center

Purchase of a KLINGELNBERG-HÖFLER P 26 CNC measuring center for automated testing of profile, alignment, pitch and concentricity deviations, as well as workpiece surface inspection.

2017 - Hänel Rotomat® storage systems for the shipping department

Installation of two Hänel Rotomat® heavy-duty storage systems in the shipping department.

2016 - New PDA/MDA system

Installation of a new PDA/MDA system to further optimize and improve production processes.

2014 - MAFAC JAVA cleaning system

Installation of a MAFAC JAVA cleaning system for environmentally-friendly cleaning of workpieces.

2013 - Okamoto rotary table grinding machine

The company purchases a high-precision Okamoto rotary table grinding machine.

2012 - Mazak Multiplex 6200Y

Investment in a Mazak Multiplex 6200Y dual-spindle turning center.

2011 - Höfler Helix 400 KK

Gear flank grinding processes are enhanced with a Höfler Helix 400 KK grinding machine.

2009 - Mazak Nexus 250

Investment in a Mazak Nexus 250 turning machine to reduce the number of outsourcing contracts.

2008 - GP 300 ES CNC

Early in the year a Karl Klink hard broaching machine with loader is put into operation. The expanded slotting department acquires a GP 300 ES CNC to introduce new gear shaping technology.

2007 - Hardinge Quest 65 and Studer S33 CNC

Hard turning technology is now possible with the addition of a Hardinge Quest 65 CNC machine. Production capacity is increased with a new Studer S33 CNC.

2006 - Reishauer RZ 400 and P40 Klingelnberg

Due to steady business growth, the company invests in a second Reishauer RZ 400 with automatic loading to expand gear flank grinding operations. A brand-new Klingelnberg P40 CNC measuring center replaces the Höfler ZP 400 in the measuring lab.

2005 - VOUMARD 110 CNC

Hänel continues to invest in the very latest CNC machines and technologies. A new VOUMARD 110 CNC machine is put into operation in the internal grinding department. A laser marking system is purchased to support the tracking of batch jobs.

2003 - “Supplier of the Year” award from Siemens and installation of a Reishauer RZ 400 system

Siemens names Hänel its “Supplier of the Year.” New technology enhances the final phases of gear grinding with the deployment of a Reishauer RZ 400 with automatic loading.

2002 - MAZAK INTEGREX 300 Y

A multifunction MAZAK INTEGREX 300 Y CNC turning and milling center is added to the turning department to increase flexibility.

1998 - Installation of multi-axis CNC turning and grinding centers with automatic loading

Start of a new era in turning and external cylindrical grinding with the purchase of multi-axis CNC turning and grinding centers featuring automatic loading.

1997 - Reishauer RZ 362 A

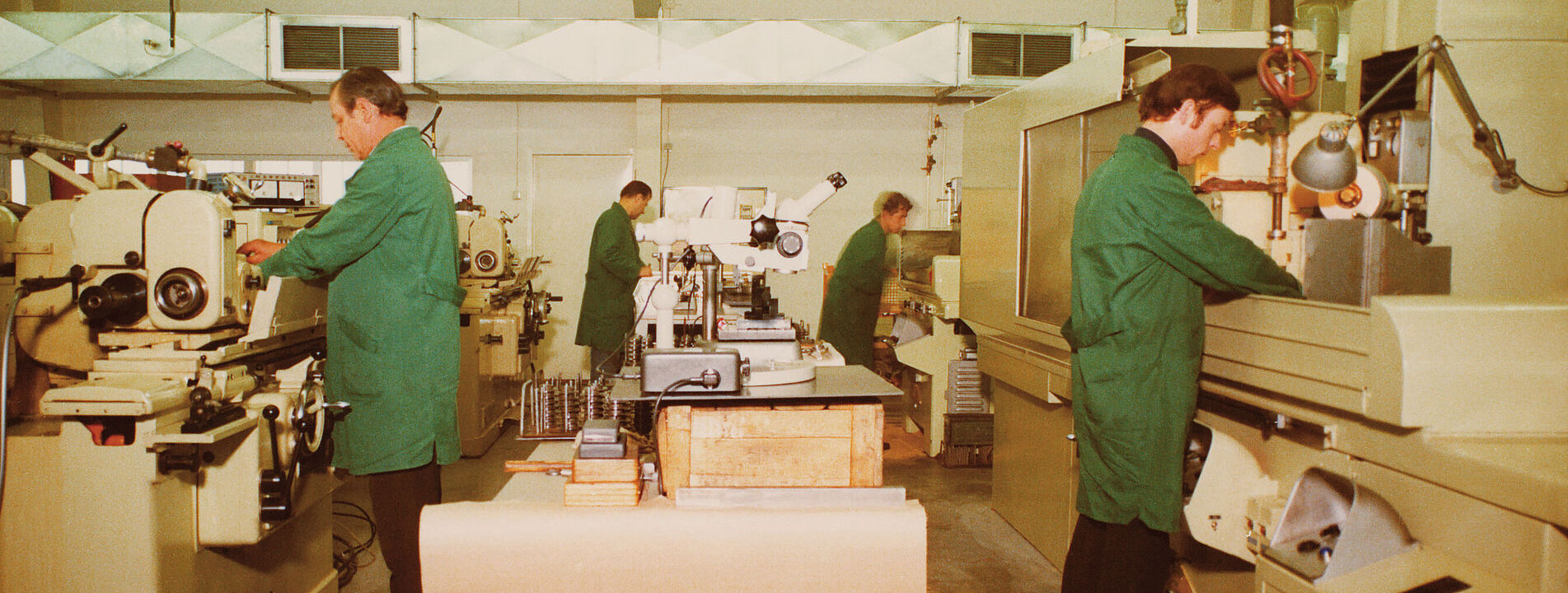

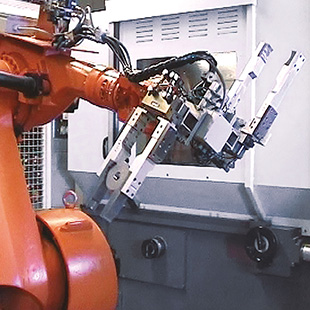

Investment in an additional Reishauer RZ 362 A with a KUKA loading robot marks the introduction of the first automated gear grinding process. The company employs some 50 people and has the latest CNC machines in all departments. All administration tasks are performed with a modern EDP system.

1996 - Reishauer RZ 362 A

Deployment of the new-generation Reishauer RZ 362 A for gear flank grinding.

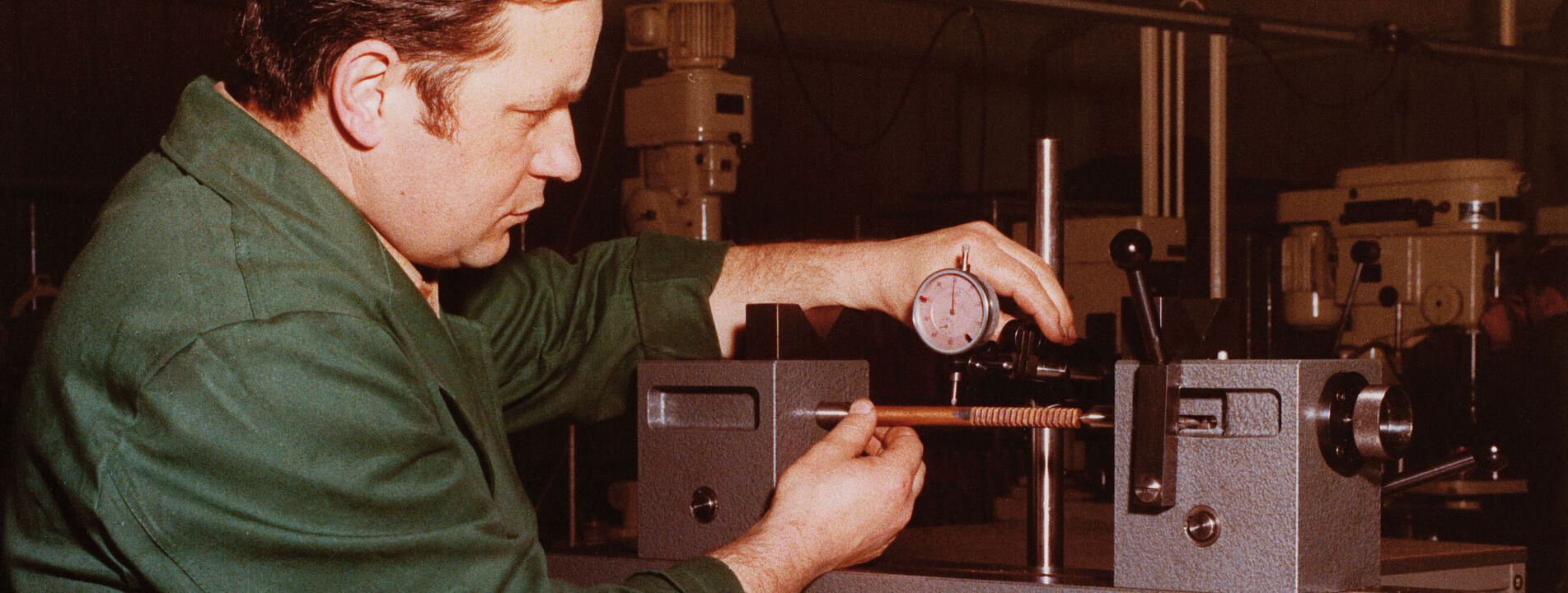

1993 - Production of high-quality premium gears

Hänel specializes in the manufacture of high-quality precision gear components. The customer base now includes many well-known companies.

1988 - New company name: Zahnradfabrik Hänel GmbH & Co KG / Hänel Precision Gears

End of Mr. Umbach's tenure and renaming of the company to "Zahnradfabrik Hänel GmbH & Co KG.”

1982 - Formation of the turning shop

Establishment of the turning shop and integration of its tasks in the company's own production.

1981 - First apprentice training programs

Introduction of apprentice training to compensate for the shortage of skilled workers.

1980 – More space added to the production area and break rooms for employees

Expansion of the production area and break rooms by an additional 800 m².

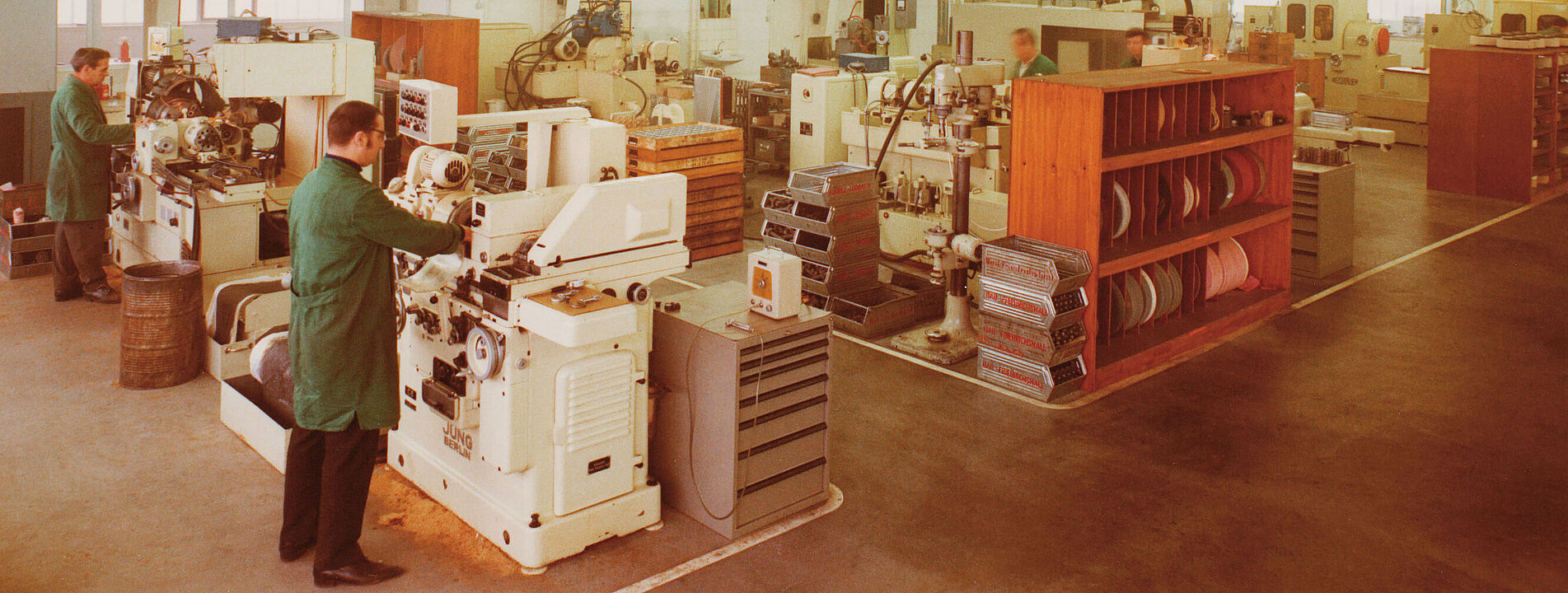

1972 - Company workforce grows to 40 employees

Introduction of a second shift in production and expansion of machinery assets, with the workforce gradually increasing to 40.

1969 - New company building completed

Construction of a new building at Siemensstraße 1 in Bad Friedrichshall. Move to the new location. The workforce at this time numbers 15 employees.

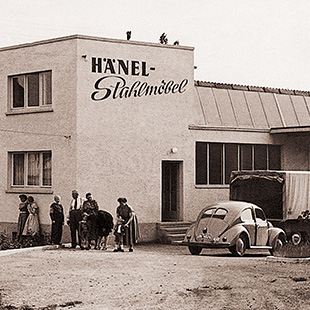

1967 - Formation of “Zahnradfabrik Hänel”

Founding of the "Zahnradfabrik Hänel und Umbach" by Gerhard Hänel and Hans Umbach in Bad Friedrichshall with four employees on the premises of Hänel Office and Industrial Storage Systems.

1953 - Formation of “Hänel Office and Industrial Storage Systems”

Gerhard Hänel founds “Hänel Office and Industrial Storage Systems” in Bad Friedrichshall, Germany.